In the last couple of decades, the CAD-CAM software has been dramatically utilized in CNC workshops worldwide mainly because of its considerable advantages in the production of metallurgical machining parts, the rationalization of production machining capabilities, and the tool stroke that maintains them very profitable.

For that reason, nowadays, computer-aided manufacturing (CAM) and computer-aided design (CAD) software enjoy widespread adoption across different industries that use CNC machines in their daily operations. So, if you’re a manufacturer and haven’t adopted this technology yet, now is the time to find out why you should start integrating CAD-CAM software into your workflow.

Below, we’ll discuss the top advantages of CAD-CAM software for CNC workshops and how they can help you achieve higher productivity. It will also allow you greater perfection in metal parts or any other type of material, and an optimized workflow for the entire manufacturing process carried out in your facility.

Below, we’ll discuss the top advantages of CAD-CAM software for CNC workshops and how they can help you achieve higher productivity. It will also allow you greater perfection in metal parts or any other type of material, and an optimized workflow for the entire manufacturing process carried out in your facility.

Increased Programming Potential

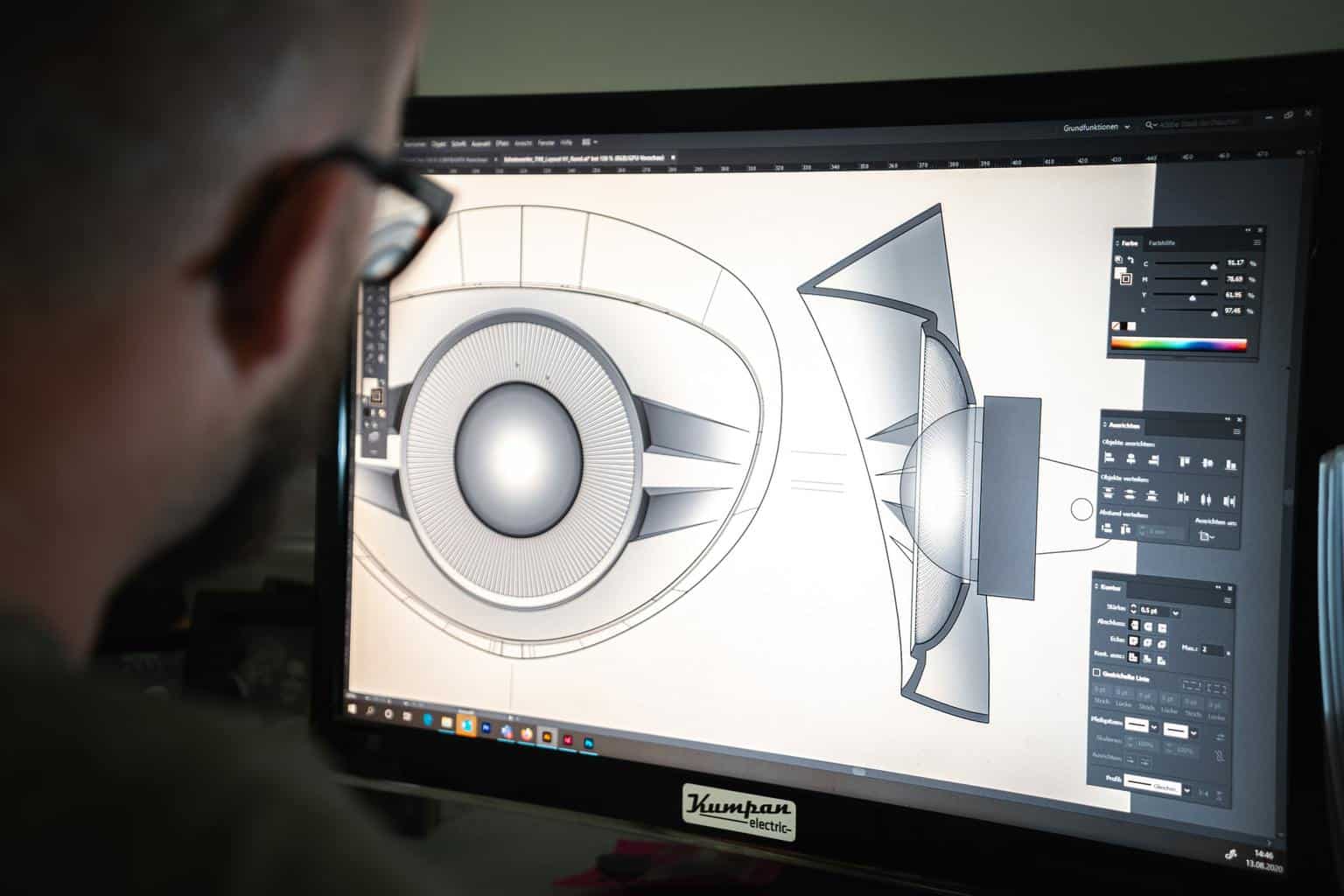

By using CAD-CAM software in your CNC machinery toolkit, first of all, you can unfold new possibilities to your business that haven’t been there before. An excellent example of this is gaining the possibility of taking on more complex, more challenging 3-axis machining jobs or adding options that make multiaxis machining easier and faster when working with 4-axis and 5-axis CNC machines.

By using CAD-CAM software in your CNC machinery toolkit, first of all, you can unfold new possibilities to your business that haven’t been there before. An excellent example of this is gaining the possibility of taking on more complex, more challenging 3-axis machining jobs or adding options that make multiaxis machining easier and faster when working with 4-axis and 5-axis CNC machines.

The CAD-CAM software can help you create and manage an optimized toolpath and numerical control programs for complex machining projects, such as CNC milling. This way, you’ll take your CNC milling services to the next level as the CAD-CAM software will entirely automate the process while offering more alternatives for toolpaths for your part programming.

It Will Make You More Accessible to Clients

By having CAD-CAM software integrated within your workshop, you can receive CAD files from customers more efficiently and faster than ever before. You can start working with wireframe files like DWG or DXF or surface and solid model files like IGES, STEP, SLDPRT, and other 3D files.

By having CAD-CAM software integrated within your workshop, you can receive CAD files from customers more efficiently and faster than ever before. You can start working with wireframe files like DWG or DXF or surface and solid model files like IGES, STEP, SLDPRT, and other 3D files.

Once you receive these CAD files, you can immediately access them, set up the toolpath for the required machining, and run pre-machining simulations that can provide valuable information for you in the quoting process, such as determining cycle times.

Moreover, with CAD-CAM software, CNC manufacturers can deliver their products to market quicker, and the final output will cost less money per piece.

You Will Be Able to Get the Best Out of Your CNC Tooling

By using CAD-CAM software, you will be able to get the best and most out of your CNC machines by using high-speed adaptive toolpath technology that delivers a wide range of benefits that all equal up to more minor tool wear, reduced cycle times, and reduction in machine wear and tear over the years.

By using CAD-CAM software, you will be able to get the best and most out of your CNC machines by using high-speed adaptive toolpath technology that delivers a wide range of benefits that all equal up to more minor tool wear, reduced cycle times, and reduction in machine wear and tear over the years.

In addition, the software will allow you to improve the cutting quality by eliminating the stop-and-go actions that are common in traditional machining. The circular cutting motions at higher speeds will allow for a permanent tool engagement with the material, more sharp cuts, and the capacity to use more of the cutting tool itself.

Adaptive toolpaths, also called trochoidal CNC milling, are frequently used with a significant depth of cut and a shallow step of the width of indent. This modern CAD-CAM-powered toolpath for 2, 3, 4, and 5-axis machines boasts more than just faster cycle times as it can improve your CNC machine productivity by over 50%.

Eliminating Costly Mistakes and Waste Through Simulation

The best CAD-CAM software provides fantastic simulation features that enable you to visually inspect the CNC machining process and detect costly tool collisions and gouges before they even reach the CNC machine. This alone makes adding CAD-CAM software to the workshop a good decision.

In addition, it can provide detailed information about the cycle times, toolpath, part deviation analysis, the ability to create simulation presentations for clients and investors, and much more. The bottom line, higher levels of simulation can allow you to utilize your CNC machine’s kinematics best through simulating machining with the actual machine tool setting and know what to expect from your projects.

Final Thoughts

In a few words, CAD-CAM software integration with CNC machining for CNC workshops and manufacturing comes with numerous benefits. The top four advantages include increased programming potential, making you more accessible to clients, making your machines more robust and durable, and eliminating costly mistakes along the way, thanks to simulation before production.

Implementing software like this can help your CNC workshop become more productive, efficient and gain a competitive edge over your rivals, all while maintaining profitability.